sales@raycontrol.com

+65 65630544

|

SALES | PARTS | SERVICES sales@raycontrol.com +65 65630544 |

|

The International Maritime Organization (IMO) has adopted the International Convention for the Control and Management of Ships Ballast Water and Sediments, in order to regulate discharges of ballast water and minimize the risk of spreading harmful aquatic organisms by ship ballast water.

Hanla IMS Co.,Ltd has developed eco-friendly EcoGuardian system for treating Aquatic Invasive Species in a ships ballast water. Treatment method is side-Stream type which enables the system to be remotely installed away from the ballast lines. The EcoGuardian system can be installed separately by unit. So relocation of other equipment and additional engineering can be minimized.

- Automatic back-flushing filter unit removes large organisms and solid particles above 50 μm

- Automatic back-flushing operation starts when the pressure difference between the water inlet and outlet reaches a certain value

- The side stream of the ballasting water goes through the electrolysis unit that generates the high concentration of TRO (Total Residual Oxidants). The concentrated stream is then injected back to the main ballasting line

- Electrolysis unit (including electrolytic cells, rectifier/transformer, booster pumps, conductivity sensor and degassing devices) produces sodium hypochlorite solution which disinfects the residual plankton, pathogens, larva or spores

- Neutralization unit adds sodium thiosulfate solution into the treated ballast water to neutralize the residual TRO during de-ballasting

- When ballasting maximum TRO concentration is limited to 9.0 mg/L

- When de-ballasting MADC (Maximum Allowable Discharge Concentration) is 0.2 mg/L TRO as Cl2

- Control system including PLC, HMI and auxiliary equipment

System GeneralThe operation of HANLA EcoGuardianTM Ballast Water Management System can be divided into three phase :

-Ballasting

-During voyage

-De-ballasting.

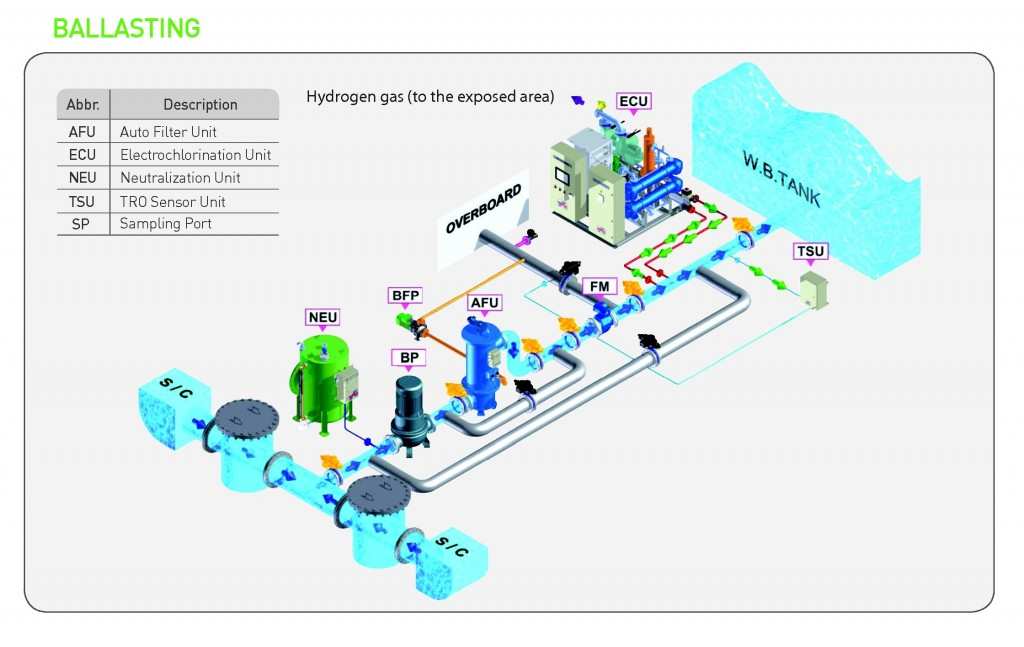

Ballasting

During ballasting process, ballasting water is first pumped through the

automatic back flushing filter unit which removes large organisms and solid

particles (above 50μm). The filter unit is installed directly at the main ballasting

line.

The side stream of the ballasting water goes through the electrochlorination unit that generates TRO of high concentration sodium hypochlorite which is then injected back to the main ballasting line. After injection, Sodium hypochlorite is mixed and diluted with main ballasting water and goes to ballast tanks. Maximum dose concentration is 9 mg/L TRO as Cl2 which is controlled by using the on-line TRO sensor. That is, EcoGuardian system adjusts the supplying current which determines hypochlorite production rate by monitoring TRO sensor.

Electrochlorination unit of EcoGuardian is designed to operate at the seawater salinity of 10 PSU or more. For operation in the low salinity water, EcoGuardian can use the seawater in the existing onboard seawater tank because this system use only small amount of seawater in comparison with the incoming ballast water flow (less than 5% of ballast water flow).

As a side reaction of electrochlorination, hydrogen gas is generated on the cathodes of cells. Because hydrogen gas is highly explosive, it should be properly vented from the system as soon as possible whenever it is produced. Hydrogen gas is separated by hydrogen separator and is diluted less than 1% of atmospheric concentration of hydrogen by forced air blowing. Finally this diluted hydrogen gas is vented to the outside of a ship. The lower explosive limit (LEL) for hydrogen is 4% and the fourfold safety of explosion limit is applied.

During voyage

The remained organisms in the ballast tank will be disinfected by the residual effect of disinfectants.

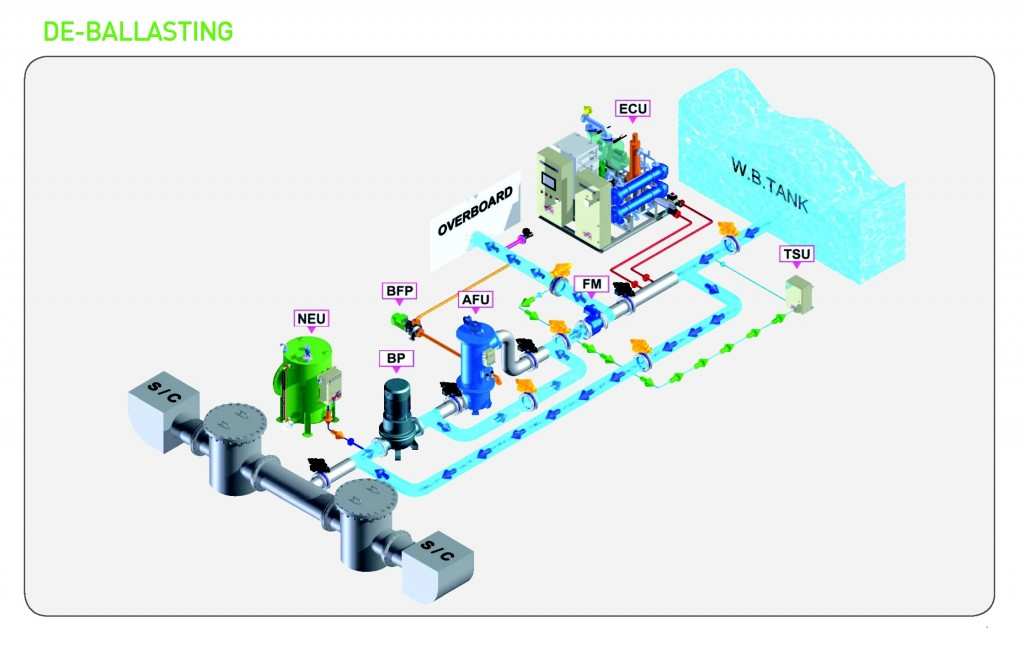

De-ballasting

During de-ballasting process, de-ballasting water passes through only

neutralization unit prior to overboard discharging. As neutralizing agent,

sodium thiosulfate is injected into de-ballasting line to neutralize the

residual TRO. The injection amount of sodium thiosulfate is controlled by

monitoring de-ballasting flow rate and residual TRO concentration.

Two TRO sensors are used to measure the residual TRO concentration at two points, before and after the neutralization unit. TRO measurement before the neutralization unit is used to measure the residual TRO concentration and then EcoGuardian Controller determines the injection amount of neutralizing agent into the de-ballasting line. Another TRO measurement after the neutralization unit is used to check that residual TRO has been neutralized properly.

Neutralization unit of EcoGuardian maintains Maximum Allowable Discharge Concentration (MADC) for 0.2 mg/L TRO as Cl2. To comply with this condition, dosing rate of sodium thiosulfate is set based on the stoichiometric ratio of TRO to sodium thiosulfate at 1:2 parts. Sodium thiosulfate is injected at the inlet of ballast pump so the residual TRO in de-ballasting water is rapidly neutralized by the mixing effect at ballast pump impeller.

Copyright © 2016 raycOntrol pte ltd. All rights reserved. All brands and product names are trademark of their respective owners. raycOntrol pte ltd assumes no responsibility or liability for any misinterpretation, loss or damage incurred as a result of any use of the information and material contained within or downloaded from this website. All parties concerned are encouraged to conduct their own information verification or confirmation.